The B6_TH range is a flexible two-chamber vacuum furnace, offering oil quenching, gas quenching and low pressure carburising all at once.

We would like to send you a personalized offer tailored to your requirements.

You can reach us by phone, comfortable via e-mail or through our contact form.

B6_TH, multipurpose multi-process vacuum furnace for high-temperature treatments

The BMI vacuum furnaces of the B6_TH family are multipurpose two-chamber vacuum furnaces for oil and gas quenching. The possibility offered by vacuum gas quenching thus helps to treat a large variety of steel grades. This furnace has a simple and compact design that limits operating and heat treatment costs as well as ground space. The B6_TH range is therefore the perfect fit for customers looking for flexibility in their equipment, such as heat treaters.

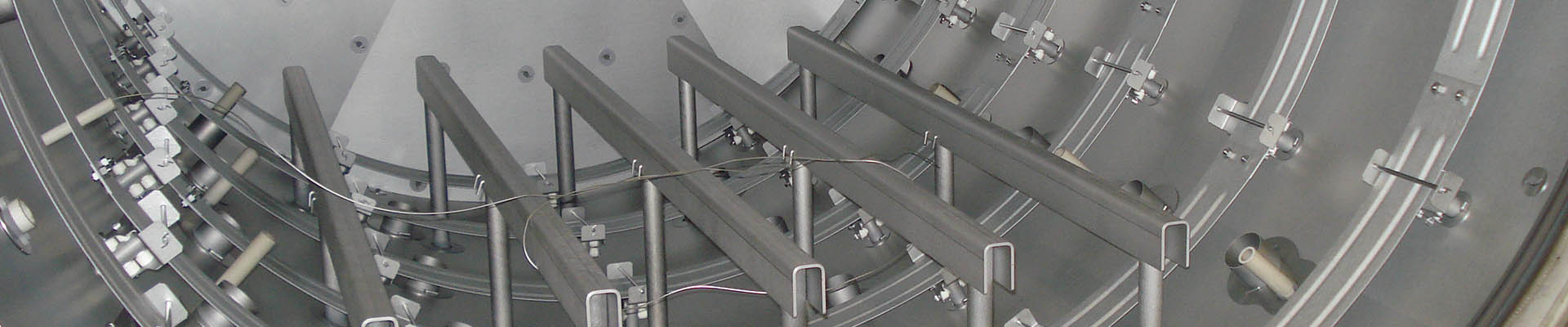

The heating chamber can be maintained at a temperature to increase productivity. The airtight door inside guarantees zero interaction of oil vapours and thus helps to reach high vacuum levels. This furnace is equipped with a fully automatic handling system that uses a hydraulically-controlled deformable parallelogram and telescope allowing a transfer time in the order of 25 seconds. The installation is fully automatic and enables perfect reproducibility of results.

BMI optionally offers, for its entire range of vacuum oil quenching furnaces, ALLCARB® low-pressure carburisation, which is distinguished by its industrial results: precise, reproducible and homogeneous. Its use is facilitated by a software assistant, which helps to calculate the cycle parameters according to the depth sought and the steel grade, while retaining the possibility of modifying them in order to optimise these carburising parameters for a specific application.

As per the selected options, this equipment will be specially adapted for vacuum treatments of steel quenching (without surface oxidation), annealing and ALLCARB® low-pressure carburising.

If gas quenching is not imperative, the clients with reproducible production, just like certain aeronautical subcontractors, prefer the single-chamber furnaces of the B5_TH family exclusively dedicated to oil quenching. For mass production, just like automobile production, our clients turn to the furnaces of the P16_TH vacuum furnace family. Clients who treat long tapering parts, like landing gears components in aeronautics, favour the range of the V6_TH vertical oil quenching furnaces.

| Cooling pressure: |

|

| Pumping unit: |

|

| Peripherals: |

|