Diversification & co-engineering approach

For many decades, BMI focused on a restricted range of products: vacuum furnaces for the heat treatment of steel parts, to be used in cutting-edge applications such as aerospace or medical. Our customers easily rely on our expertise because our furnaces have been tested and proven in industrial conditions.

We had already started our way towards diversification but the Covid-19 crisis along with its market changes have encouraged us to go faster. We have to learn to work differently and to get out of our comfort zone by putting our skills and know-how into new projects.

How do we do it in a practical and effective manner ? For example, we design partly completed machineries using a co-engineering approach with our customers. Our customers thus become our partners.

These projects are not technically challenging for us, they do not represent big sales revenue either but at the request of our customers we sometimes develop other machines.

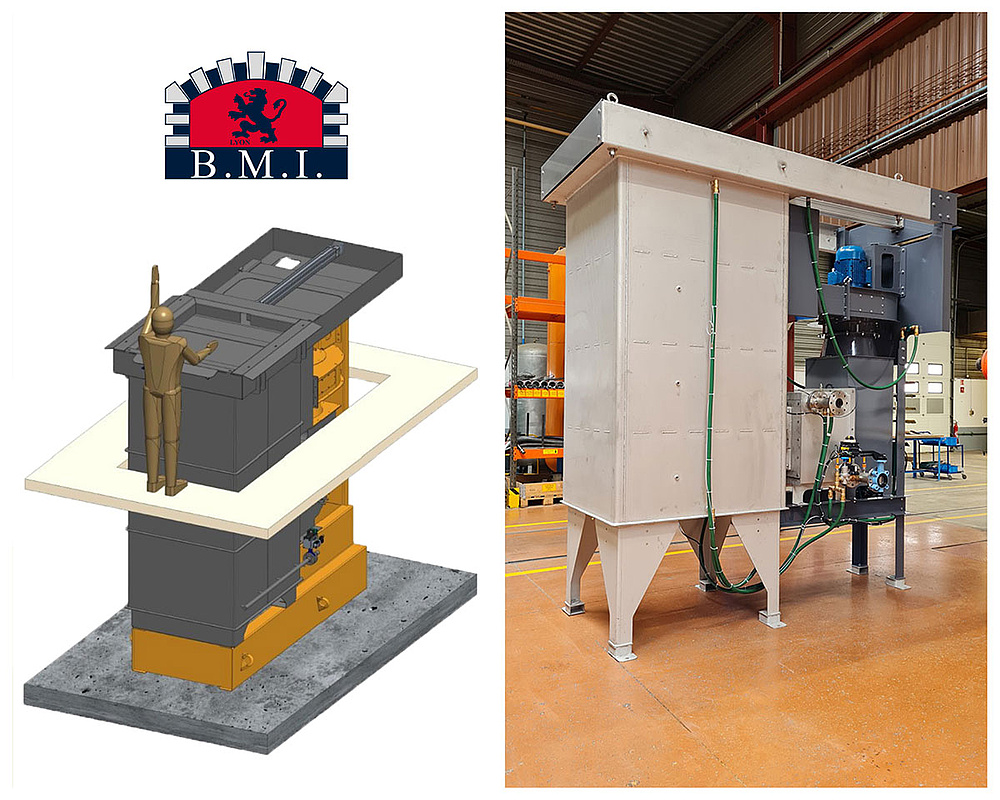

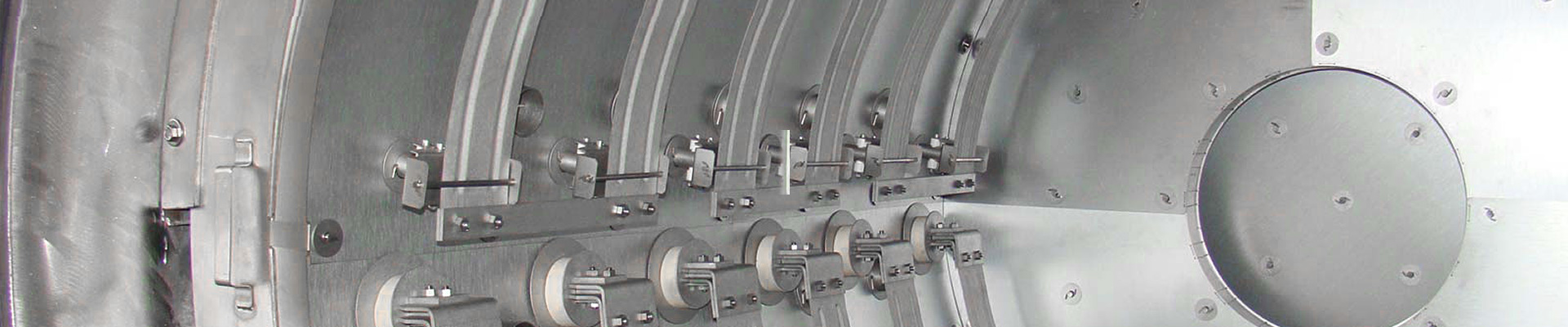

The latest example of co-engineering machine we designed was a simple box-type cooling module under inert gas with external turbine and exchanger. This machinery was to be integrated into a complete production line of salt bath nitriding, manufactured by the customer himself. BMI’s scope of supply was limited to engineering and design, manufacturing and functional analysis of the cooling module. And that’s all. There was no vacuum purge, no heating, no instrumentation or control system, no pre-acceptance protocol and no commissioning. It is the kind of RFQ we would usually decline because it does not match our core business strategy (vacuum heat treatment furnaces) but we studied the project with a new angle and we decided to go for it.

Let us introduce you to BMI’s cooling module type CRV56T220.