BA5_ Furnace

Benefits of BMI’s VAB Furnace Technology

-

Reliable and repeatable brazing results

-

Fully automated operation for optimal process control

-

Superior joint integrity and surface finish

-

No flux required, reducing contamination and post-process cleaning

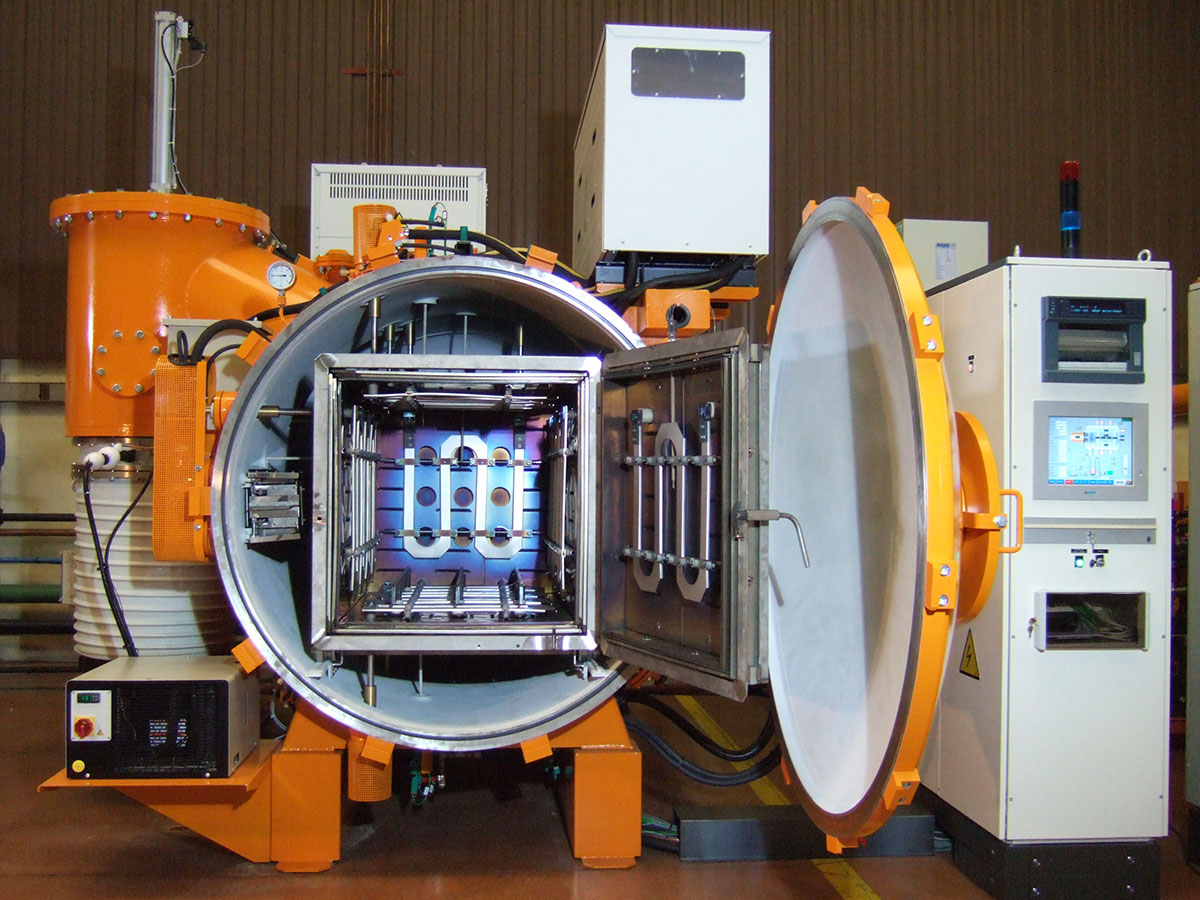

The BA5_ vacuum aluminum brazing furnace is the solution of choice for manufacturers seeking high precision, cleanliness, and consistency in aluminum welding and brazing operations under vacuum.

The BMI BA5_ series is a high-performance line of VAB furnaces (Vacuum Aluminum Brazing), engineered specifically for vacuum aluminum brazing and aluminum welding applications. These vacuum furnaces are designed to deliver clean, oxidation-free parts, meeting the most demanding aerospace and industrial standards.

High-Precision Vacuum Aluminum Brazing Furnaces

The BA5_ VAB furnace is equipped with:

-

Full-metal insulation ensuring low degassing for ultra-clean environments

-

Powerful pumping units to achieve and maintain the high vacuum levels essential for aluminum brazing

-

Six independently controlled heating zones, guaranteeing thermal uniformity of ±3 °C across the entire workload

This precision engineering makes the BA5_ series ideal for vacuum brazing of aluminum components, including:

-

Heat exchangers (plates, honeycombs, etc.)

-

Sub-assemblies for aerospace and aeronautics (e.g., waveguides)

-

Lightweight structural parts requiring clean, strong brazed or welded joints.

Technical Details

450 x 450 x 600 mm – 1000 x 1000 x 2500 mm

150 – 800 kg

Metal insulation

10-6 mbar

Max 700°C

GRAPHTIL® man-machine interface

Cooling pressure 1,2 bar abs

Heat Treatment Processes

- Annealing

- Ageing

- Stress relieving

- Aluminum brazing

- Special alloy degassing

A few references

Request a quote

We would like to send you a personalized offer tailored to your requirements.

You can reach us by phone, via e-mail or through our contact form.